Net of wire rope

Key words:

Net of wire rope

Classification:

Detailed introduction

Beckett's wire rope non-destructive tester is a supplier of testing equipment and specific services based on the "permanent magnet-magnetic flux leakage" principle. No matter what type and size of wire rope, no matter what kind of detection environment, 100 can easily do. At present, the non-destructive testing instrument has been widely used in domestic and foreign mines, lifting, elevators, ropeways, bridges, overhead transmission lines and other fields of wire rope detection.

The 100 kett wire rope non-destructive detector has coal safety certificate, mine safety certificate and explosion-proof certificate. It is the preferred for mine hoist wire rope detection, ropeway wire rope detection, crane wire rope detection, elevator wire rope detection and friction hoist wire rope detection. The steel wire rope detector can detect the metal cross-sectional area damage of 6-150mm steel wire rope and the corrosion of local broken wire rope.

Performance index

1. Data collector

The data collector is compatible with all types of heads. The truly secure built-in data logger can store inspection data of up to 30,000 meters of wire rope.

The LMA and LF data are displayed separately on two displays: LMA in% and LF in MV. In addition to the number of LF in each lay length, the current rope distance and rope speed are also displayed and stored.

The data collector is battery-powered and has energy-saving functions.

The sturdy membrane keyboard and leather bag ensure that the device is protected from dust and rain.

The data collector is a lightweight handheld device that can be easily connected to the head and travel along the rope; in this case, the data collector can be connected to the head with a short cable. In addition, the telemetry system will also provide a wireless connection between the data collector and the computer.

Dimensions |

85 x 35 x 230mm |

Weight |

0.7kg |

Power |

AA rechargeable battery |

Continuous working hours |

More than 6 hours |

2. Head

The head consists of two halves connected together by a hinge. Before testing, the magnetic head was mounted on the rope and the two halves were closed together.

MH 60-85,MH 80-120 and MH 100-150 have detachable half heads and are assembled on steel ropes in different ways.

The sensor cells within the magnetic head include Hall effect sensors and/or coil sensors. The use of different sized sleeves within the head aligns the head with the rope and protects the sensor unit. Magnetic heads for larger size rope detection, namely MH 60-85,MH 80-120,MH 100-150 are aligned with special spring-loaded wheels.

Each head is equipped with a distance counter to provide an accurate measurement of the current position of the head along the rope.

The integrated MB 8-24 has both a magnetic head and a data collector, and is installed in the same device together with the front panel display and membrane keyboard |

|

Detecting rope diameter |

8-24mm |

Dimensions |

348x 88x 224mm |

Weight |

3.5kg |

Detection speed |

0-1 m/s |

Sensor unit |

Group 1 |

Sleeve |

8 sets |

Head MH 6-24F with removable sensor unit and sleeve |

|

Detecting rope diameter |

6-24mm |

Dimensions |

264x 188x 66mm |

Weight |

3kg |

Detection speed |

0-2 m/s |

Sensor unit |

Group 3 |

Sleeve |

6 sets |

The head MH 20-40 is equipped with a non-removable sealed sensor unit and a replaceable sleeve |

|

Detecting rope diameter |

20-40mm |

Dimensions |

330x 205x 190mm |

Weight |

8.7kg |

Detection speed |

0-2 m/s |

Sensor unit |

Group 1 |

Sleeve |

4 sets |

The heads MH 24-64 and MH 40-64 have similar design, size and weight. MH 24-64 is equipped with a detachable sensor unit, MH 40-64 is equipped with a non-detachable sealed sensor unit. |

||

Detecting rope diameter |

24-64mm |

40-64mm |

Dimensions |

330x 235x 195mm |

330x 235x 195mm |

Weight |

15kg |

15kg |

Detection speed |

0-2 m/s |

0-2 m/s |

Sensor unit |

Group 3 |

Group 1 |

Sleeve |

8 sets |

5 sets |

The MH 24-64M3 head is equipped with a detachable sensor unit, built-in Hall effect sensor and coil, and has higher LF sensitivity |

|

Detecting rope diameter |

24-64mm |

Dimensions |

330x 235x 195mm |

Weight |

15kg |

Detection speed |

0-2 m/s |

Sensor unit |

Group 8 |

Sleeve |

16 sets |

The magnetic head MH 60-85 consists of two independent modules, which are connected to the rope by special tools provided in the kit. The MH 60-85 is equipped with a non-removable Hall-effect sensor unit and a removable coil sensor. The head is flush with the cord via an adjustable roller |

|

Detecting rope diameter |

60-85mm |

Dimensions |

690x 526x 288mm |

Weight |

60kg |

Detection speed |

0.2-1.5 m/s |

Coil sensor |

Group of 5 |

3. Product features

It is suitable for testing stranded, spiral, semi-sealed and fully sealed steel wire ropes made of smooth wire or galvanized wire. It conforms to ASTM E1571,EN 12927-8,IMCA SEL 022,M194; SEL 023,M197. It consists of a data collector and a magnetic head connected by a special cable with a length of 5 or 8 meters. The magnetic head is designed to inspect ropes from 6 to 150mm in diameter. The all-in-one device MB 8-24 is designed to mount the head and data collector together. When detecting, the wire rope is moved through the magnetic head or the magnetic head is moved along the rope. LMA can be measured at the same time, and LF can be displayed in the form of internal and external broken wires, pitting corrosion, solder joints, etc. It can also display the speed of the wire rope and the current position of the instrument along the wire rope. The data collector is compatible with all heads and has a download function. Detection data is Wintros by dedicated software©After downloading from the base unit to the computer, it will be displayed as LMA,LF and detected speed. Data can also be Wintros via software RTV©Online output.

The data collector and magnetic head for wire rope inspection with a diameter of 64mm or less can be installed in a carrying case with a shoulder strap design, which is very easy to carry. Larger size devices are stored in sturdy cases. The instrument operates at an ambient temperature of -10 to 50°C. The instrument has a corresponding explosion-proof rating.

In some cases, such as when the cable is detected through a limited channel, when the data collector is activated and installed on the head to collect data, the head should move along the cable. The wireless mode can be implemented on a computer to receive data from the data collector online. It can also be installed on a wire rope system for monitoring wire ropes. The data collector and MH 20-40,MH 40-64 are IP65, and the other heads are IP54.

1. Large range of detectable wire ropes: wire ropes with a diameter of 6~150mm can be detected, including wire ropes with various structures such as round strands, triangular strands, flat strands, and special-shaped strands.

2. The main engine of the steel wire rope detector is less than 700g, which is relatively light in the same type.

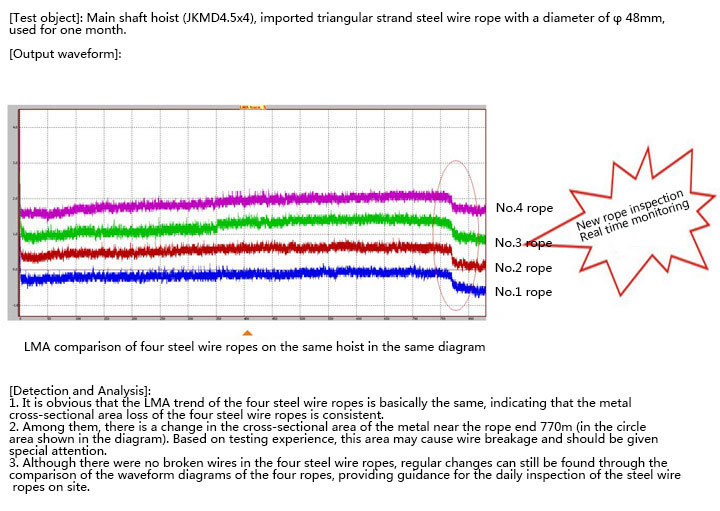

3. The steel wire rope detector has good repeatability and high consistency for many times: the deterioration speed and deterioration law of the steel wire rope can be mastered through comparative detection.

4. High detection accuracy: strong magnetic detection. Metal cross-sectional area loss and wire breakage signals are sensitive and accurate.

5. Simple operation: the output waveform diagram is simple, intuitive, easy to learn and easy to understand, and the waveform diagram can be filtered and compared, and the result is clear at a glance.

6, detect different diameter steel wire rope to replace the corresponding lining can be; After the lining is worn, it is not necessary to replace the entire magnetic head, only need to replace the cheap lining

7. The detection instrument has dual LCD screens, the result is very intuitive; sound and light alarm, intuitive display of the result.

8. The instrument has powerful software processing capabilities to filter and cut noise; optional 8-channel display, automatic report generation;

9. Strong database support: The company has been engaged in wire rope detection for many years and has rich field experience. It has collected a large amount of detection data and established a wire rope detection database.

It can effectively predict the remaining service life of the wire rope.

4. The significance of selecting steel wire rope detector

1, instead of visual inspection, high efficiency, fast, and provide an objective and intuitive basis for the detection of wire rope.

2. It can accurately measure the wear of the metal cross section of the wire rope.

3. It can not only detect the external broken wire of the wire rope, but also detect the internal broken wire of the wire rope.

4. Through the comparison of multiple ropes under the same working condition and the comparison of the same rope head for many times, the deterioration speed and deterioration law of the steel wire rope can be grasped intuitively.

5, accurate assessment of the remaining life of the wire rope, to achieve scientific rope.

6, reliable prevention of wire rope broken rope accident, to ensure safe production.

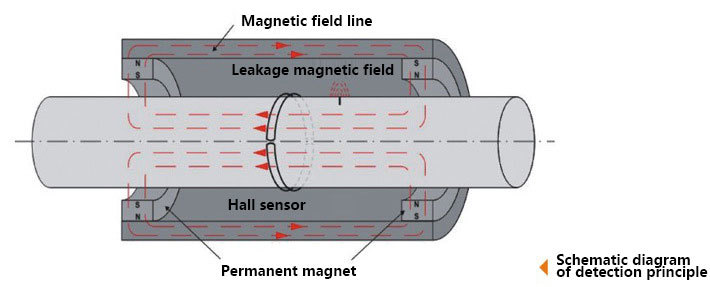

5. Detection principle

There are many reasons for rope degradation, and the strength of the rope will gradually decrease with the life cycle. For safe operation, the wire rope should be checked regularly and scrapped in time. However, prematurely scrapping wire ropes is not only wasteful, but also costly. Examining the data can make a sound decision as to whether the rope should be scrapped or can continue to be used. The company tester is a dual-function testing instrument that measures the loss of the metal cross-section (LMA) and shows local defects (LF) by means of non-destructive testing. The LMA is a relative measure of the material lost at locations along the wire rope, measured by comparing the reference point (measured with an instrument) on the wire rope that represents the largest metal cross-sectional area. LF is a discontinuity in the rope, such as a broken rope or corrosion pit, which can reduce the integrity of the rope at that location.

As shown in the figure, the wire rope detector adopts the principle of permanent magnet and magnetic flux leakage. When testing, first use a set of permanent magnets to magnetically saturate the wire rope. Then, the magnetic head wrapped in a wire rope runs at a relatively uniform speed. Any defect in the wire rope, such as broken wire, wear, rust, etc., will cause changes in the amount of magnetic flux leakage and magnetic flux, which will be captured by the Hall sensor, converted into electrical signals, and output intuitive analog signals.

6. Test parameters

According to the standard ASTM E1571-11 "ferromagnetic wire rope electromagnetic detection method", the wire rope detection mainly detects two parameters:

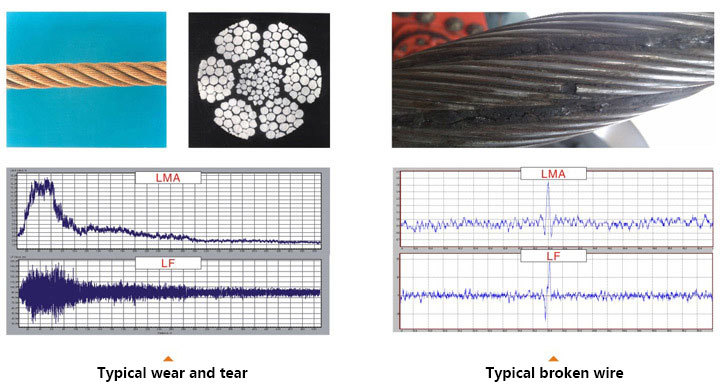

LMA (metal cross-sectional area loss): focuses on the defect degree of the metal area in the wire rope, and outputs a comparative value by comparing the detection position with the reference position (I. e. the position of the largest metal cross-sectional area in the wire rope), which is a relative measurement value in%. The larger the value, the more serious the metal defect.

LF (local damage): focus on the discontinuity in the wire rope, such as broken wire, serious corrosion pits, etc. At the damage position, a leakage magnetic field is formed, and a voltage signal is output, unit mv. The size of the value is related to the length of the fracture and the degree of damage.

LMA and LF images

Left: The loss of LMA metal cross-sectional area reaches 12% in the range of 20m ~ 80m.

Right figure: The rope at the position of 83.4m shown in the figure shows a peak signal in the waveform of LMA metal cross-sectional area, and the loss of metal cross-sectional area reaches 0.6. At the same position, the signals of wave crest and wave trough appear in the LF local damage diagram, which indicates that the steel wire at this position is discontinuous, causing magnetic field leakage. After analysis, there is one broken wire in this position.

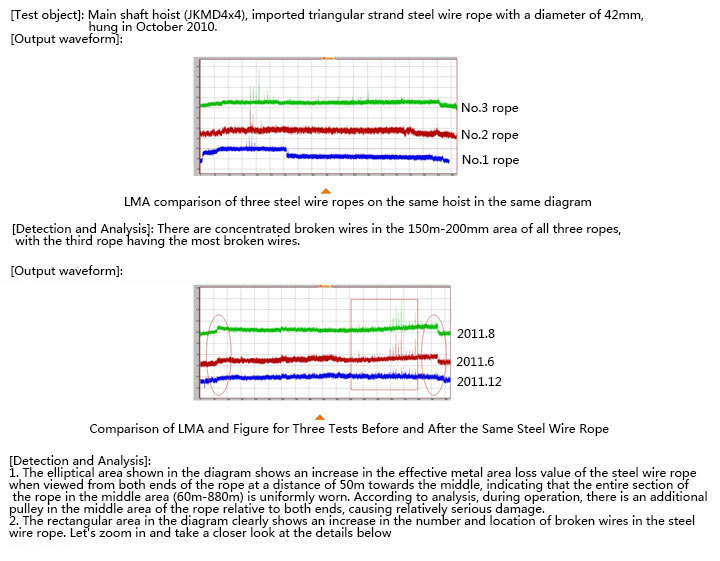

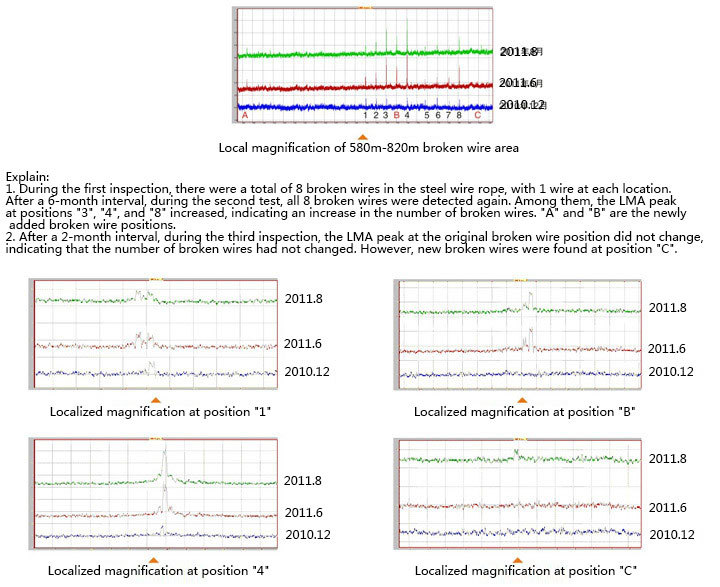

7. Test cases

Huainan Mining Wangfenggang Coal Mine

Huainan Mining Dingji Coal Mine

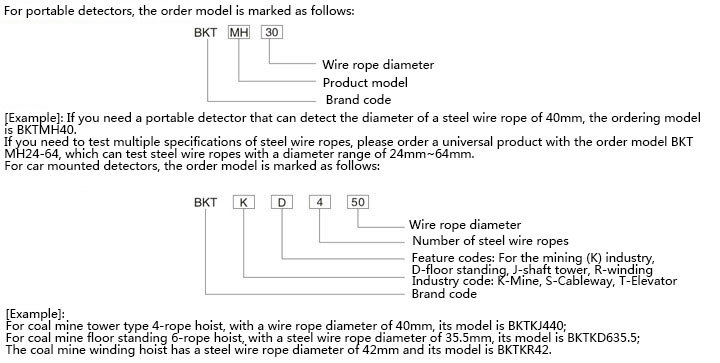

8. Ordering model

9. Quality Assurance

(1) Free operation training, on-site installation and commissioning, and technical guidance.

(2) The quality of the Hall sensor is guaranteed for 1 year, and the quality of the whole machine is guaranteed for 2 years.

(3) lifelong technical support.

Previous:Net of wire rope

Related recommend

Product inquiry

SAF Coolest v1.3.1.1 设置面板

GAGSD-ZGYF-JXSVE-SAS

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page