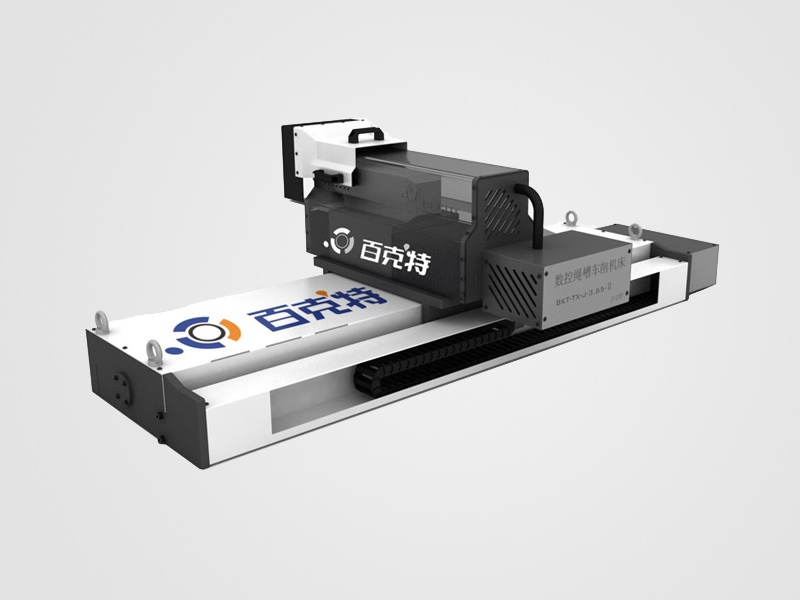

CNC rope groove turning device

Key words:

CNC rope groove turning device

Classification:

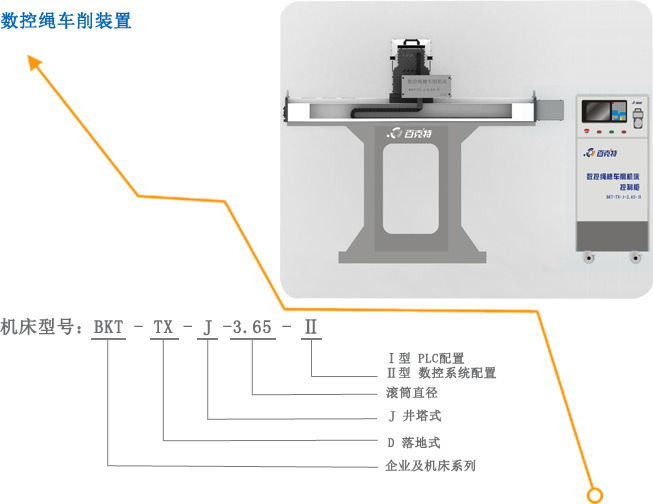

Detailed introduction

The numerical control rope groove turning device is a special equipment designed and developed by Luoyang Baikete Company for the cutting of mine hoist liners and sky wheel liners. The machine tool can effectively solve the problems of old-fashioned cutting equipment when cutting rope grooves, such as gnawing knives, shaking knives, low cutting accuracy, long cutting time, low efficiency, and high labor intensity. It is easy to operate and has high safety and efficiency. After the machine is installed and debugged, it has a unified benchmark, and it is very easy to achieve the consistency of the depth of the cutting rope groove after cutting multiple rope grooves, so as to ensure the same bottom diameter of the rope groove. By comparing the deep grinding data of rope groove cutting before and after cutting, it is easy to judge the wear degree of a rope groove, and provide reference for the adjustment and maintenance of the wire rope in the mine.

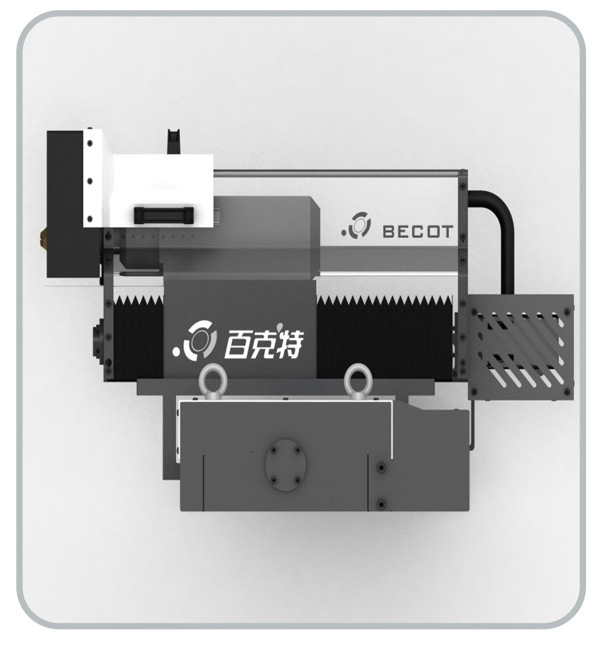

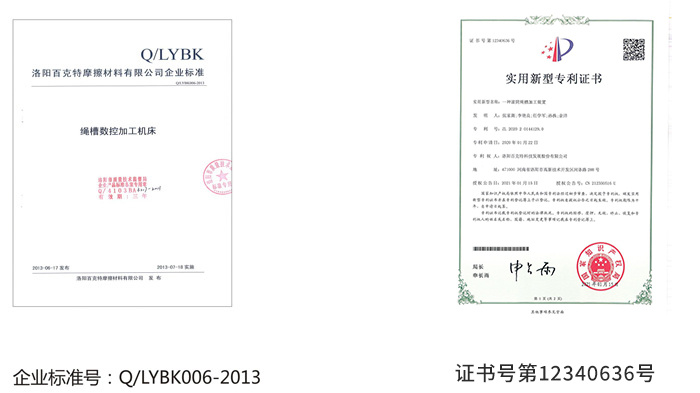

The numerical control rope groove turning device is two axis systems X-axis and Z-axis perpendicular to each other. Each axis system is controlled by numerical control system or PLC system for linear movement. It is equipped with high-speed spindle motor to realize high-precision, high-efficiency, stable and reliable cutting of rope groove. Through the cutting and maintenance of the rope groove, the wear cycle of the wire rope can be prolonged, the wire rope can be well protected, the service life of the liner can be prolonged, the stability of the friction drive system can be improved, and the needs of customers can be well met. The machine has a pure Chinese interface, simple operation, saving maintenance time occupied by rope groove cutting, improving production efficiency and reducing labor intensity. It is a sharp tool for mine and hoist rope groove maintenance and has won many patents at home and abroad.

1. Features of mechanical equipment

(1) do not shake the knife, do not bite the knife

Avoid damage to the friction lining and extend the service life of the friction lining and wire rope

(2) high processing finish and roundness

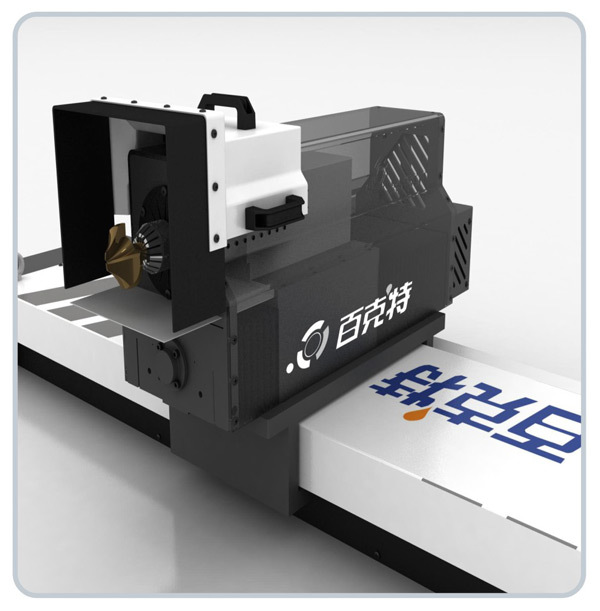

The high-speed motorized spindle selected by the machine tool has the advantages of high speed, high precision and high output power. At the same time, the motorized spindle also has the advantages of compact structure, light weight, low inertia, low vibration, low noise, fast response, etc., and has high speed and high power., Simplify the machine tool design, easy to realize the spindle positioning, greatly improve the cutting speed of the tool, and the surface finish and roundness of the processed rope groove are high.

(3) The equipment has good sealing performance, which is convenient for daily maintenance and maintenance

The machine bed adopts sealing design, which can effectively prevent the cutting powder, oil and other debris from entering the machine tool and affecting the normal operation of the machine tool when the cutting rope groove is in progress.

(4) Simple operation, low labor intensity and high safety factor

Users can choose CNC operating system or electrical PLC operating system according to their needs. All actions of the machine tool are controlled by precise electrical procedures. Each axial position can be set through the electronic display screen for specific feed, without any manual operation. The safety factor is high.

(5) Precise feed control, high cutting accuracy and consistency

According to the field conditions, the specific feed in each direction can be set, the minimum setting value is 0.001mm, and each operation detail can be monitored and adjusted. Fully ensure that the diameter of the rope groove after all processing is consistent, can effectively adjust the tension of the wire rope, shorten the adjustment stroke of the rope adjustment cylinder, and fully ensure that the hoist system runs under the same tension condition.

(6) Using the original installation foundation, the installation method is flexible and convenient

The installation of the machine tool can use the original supporting installation foundation base: when the equipment is installed on site, the rope groove cutting can be carried out after the on-site technical personnel measure, install, align, fix and other processes.

(7) High cutting efficiency, saving 80% of working time compared with traditional equipment

During the normal production and maintenance time of each coal mine every day, the whole process of machine tool installation, alignment, debugging, cutting rope groove, site cleaning and normal production can be completed. The cutting process is not restricted by the direction of rotation of the drum, and both forward and reverse can be cut.

2、Equipment application field

3. Technical characteristics

(1) Autonomous, humanized electrical procedures and program operation interface.

In addition to the standardized PLC operating procedures and numerical control operating procedures sold by the company, targeted machine tool operations, processing procedures and program operation interfaces can be written according to on-site work conditions and customer requirements to better serve customers and production sites.

(2) Real-time monitoring and feedback system

The operator can adjust the various setting parameters of the operating equipment according to the data monitored in real time by the program operation interface, so as to avoid the operator's blind operation, work errors and influence the normal production work.

(3) CNC operation mode, precise control program

In the design of the machine tool feed structure, the ball screw and servo motor are used to achieve precise axial control. Our company can also configure the grating ruler, laser ranging device, ranging wheel and other measurement feedback devices according to customer requirements.

(4) the traditional turning process to milling process

The conversion from the traditional ordinary lathe processing technology to the numerical control milling processing technology greatly improves the production efficiency, ensures the high precision and high efficiency.

(5) Diversified modes of operation

In the operation mode, the touch screen and wireless hand wheel operation mode can be used.

(6) Intelligent alarm monitoring interface

It can be used to monitor the abnormal working conditions of various equipment in the operation of the equipment, and the user can repair the equipment according to the system alarm prompt.

4. Product selection

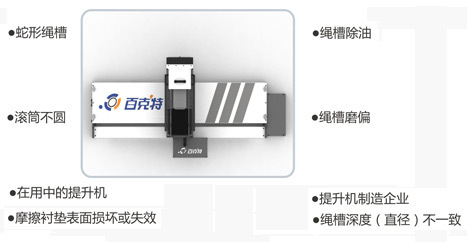

5. The significance of cutting rope groove

(1) Fully ensure that the diameter of the rope groove after all rope groove processing is consistent, which can effectively adjust the tension of the wire rope, shorten the adjustment stroke of the rope adjustment cylinder, significantly reduce the broken wire of the wire rope, extend the service life of the wire rope, and fully ensure The hoist system runs under the same tension condition;

(2) It can effectively solve the problems of the serpentine rope groove, rope groove wear and the drum is not round during the use of the friction liner;

(3) High-speed motorized spindle can provide higher cutting speed, and the surface finish and roundness of the processed rope groove are higher;

(4) The problem of surface damage or material failure of the friction liner can be solved by cutting the rope groove.

6. Instructions for ordering

This equipment is non-standard equipment, suitable for cutting and trimming the lining rope groove of the friction wheel and the top wheel of the friction hoist. Please refer to the technical agreement specification for the type number of the equipment. Before the equipment is manufactured, our company's technicians need to go to the customer's unit to measure the key dimensions of each part of the hoist. The corresponding installation base and machine tool equipment are designed to facilitate the installation of the CNC rope groove turning device.

The equipment supply cycle is four months.

Other: can be ordered according to the special requirements of customers, processing.

Previous:Net of wire rope

Next:Non-destructive testing device for steel cable of cable-stayed bridge

Related recommend

Product inquiry

SAF Coolest v1.3.1.1 设置面板

GAGSD-ZGYF-JXSVE-SAS

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page