Service process

Survey site

01

programme

02

debugging

03

detection

04

assess

05

Issue report

06

Maintenance advice

07

Survey site

Fixed

Choose the appropriate fixing method

Match

Select the matching sensor and bushing, install it in place, and check whether the link is normal.

Structure

Structural information of the tested wire rope: brand, diameter, structure and service life.

Attention

In particular, structural parameter information: Metal cross-sectional area, outer wire diameter.

Inspection and calibration

Note: In order to ensure that the reference datum of each test is consistent, it is best to use the method of calibration on the standard sample rope.

Program Development

Detection of floor type multi-rope friction hoist

Detection of well tower multi-rope friction hoist

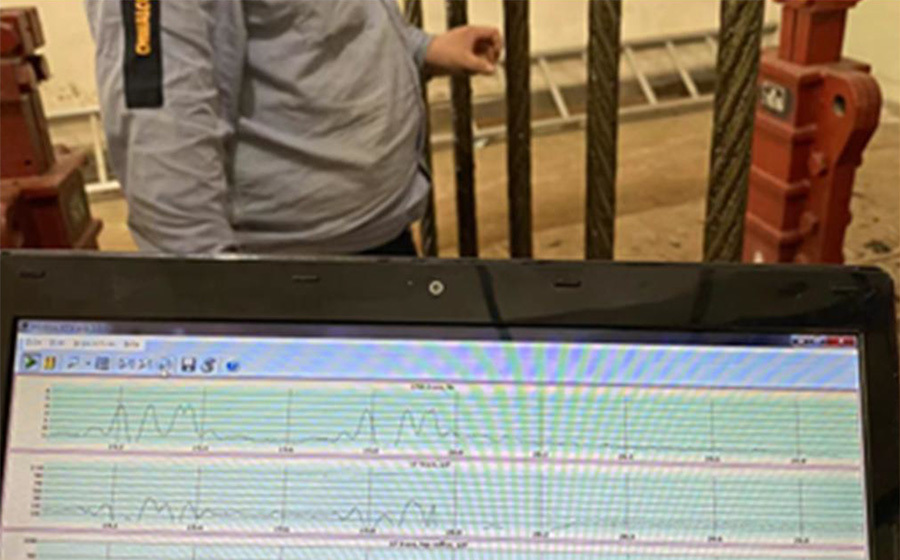

Implementation of detection, analysis and evaluation

Standard speed 0.5~2 m/s

Issue report

The deterioration speed of wire rope damage is a gradual process. Our company recommends the use of regular inspection methods to grasp the deterioration trend of wire rope.

According to the GBT21837 "Electromagnetic Testing Method for Ferromagnetic Wire Rope" and wire rope scrapping standards of various industries, our company provides customers with "Wire Rope NDT Report" with CMA and CNAS double certification to evaluate the health status of wire ropes.

SAF Coolest v1.3.1.1 设置面板

GAGSD-ZGYF-JXSVE-SAS

无数据提示

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page