① Fixed pulley

② Traction cable

③ Tested bridge cable

④ Detection equipment

⑤ Simple winch

⑥ Fixed pulley

Detailed introduction

A large number of suspended bridges and cable-stayed bridges are in service in different parts of the world. Wire ropes are an important part of such bridges because they carry the main structure of the bridge. They withstand vibrations caused by wind and traffic, and may be subject to corrosion in harsh environments, such as rain and air pollution. The wire rope will also age over time, so it needs to be checked to prevent accidents. Non-destructive testing can be done in different ways. Non-destructive testing is an effective method to obtain important information of wire rope. Magnetic Flux Leakage (MFL) is currently recognized as the inspection method of wire rope, MFL instrument can detect the loss of metal cross-sectional area caused by corrosion, and provide the location of internal and external broken wires for visual inspection.

A bridge cable wire rope detection/flaw detector

The Magnetic Flux Leakage (MFL) Tester includes a battery-powered base unit with different sizes of heads, Wintros and Wintros RTV software. The Wintros software is able to process the data after detection, Wintros the RTV software can generate the data map online.

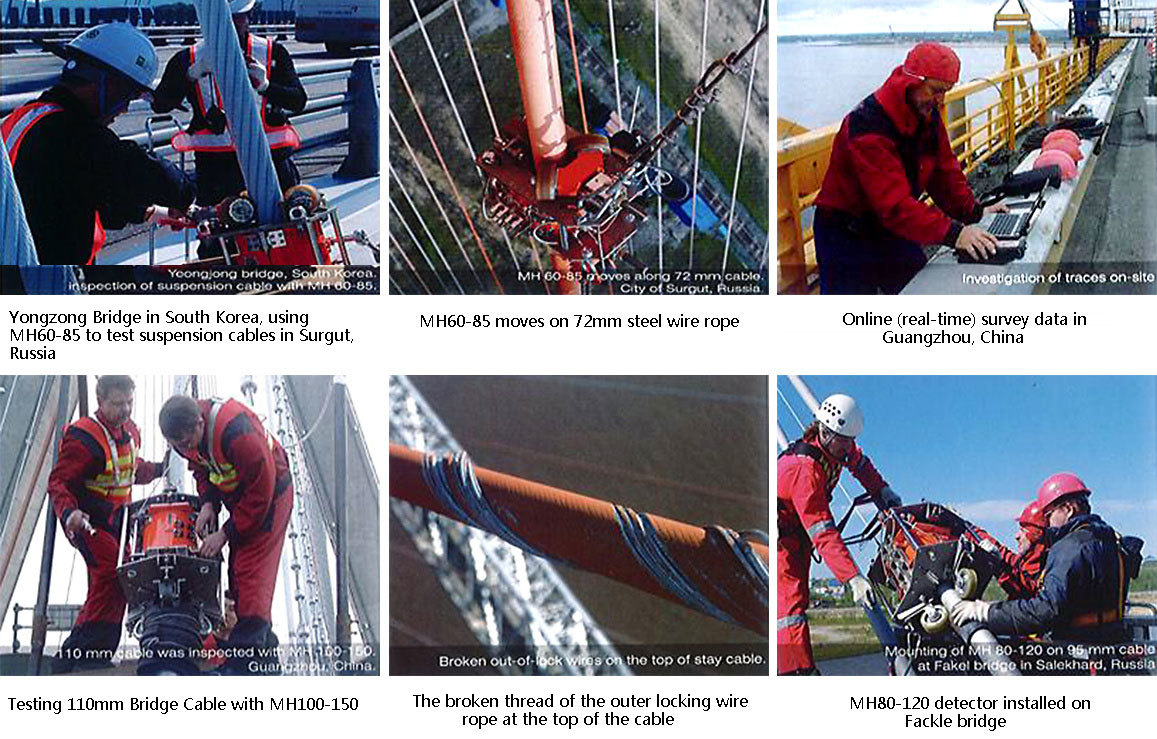

The basic unit is fixed on the magnetic head, and the magnetic head moves up and down along the wire rope to collect data and store it in the basic unit. The magnetic head is moved smoothly along the wire rope by an electric winch. For magnetic heads with a detection diameter of less than 64mm, they can be carried and moved by manual climbing and operating on the bridge deck. The Introns detector can detect the diameter range of 6~150mm wire rope. The tester moves smoothly on the wire rope without damaging the wire rope or the wire rope protective coating. The base unit can operate the telemetry system, and the remote laptop can receive the data and display it online through the Wintros RTV software.

To detect slings with parallel strands, we developed an electromagnetic head EMH-300. This head is used to inspect slings up to 300mm in diameter. It can detect 1 broken strand in a sling with a total of 100 strands.

Technical parameters of wire rope inspection/flaw detector for second bridge cable

The equipment consists of four parts: detection head, data transmission cable, data memory and software.

1. Test head type and parameters

Model |

Dimensions |

Weight |

Speed m/s |

Temperature °C |

Protection level |

BKT6-24 |

235 × 230 × 64 mm |

3kg |

0-2 |

-20- 50 |

IP54 |

BKT24-64 |

330 × 235 × 190mm |

15kg |

0-2 |

-20- 50 |

IP54 |

BKT60-85 |

690 × 526 × 288mm |

60kg |

0-1.5 |

-10- 50 |

IP54 |

BKT80-120 |

895 × 520 × 440mm |

80kg |

0-1.5 |

-10- 50 |

IP54 |

BKT100-150 |

950 × 550 × 490mm |

112kg |

0-1.5 |

-10- 50 |

IP54 |

BKT125-300 |

950 × 550 × 490mm |

50kg |

0-0.5 |

-10- 50 |

IP44 |

2. Data storage

The bridge cable wire rope detector is compatible with all detection heads, basic function setting parameters, dual-screen real-time display and data storage. Size 230 × 85 × 35mm, weight 0.7kg, rechargeable battery power supply, automatic calibration, LMA and LF dual-channel synchronous detection, capable of storing up to 32000m wire rope detection data, acousto-optic alarm function, and universal USB interface.

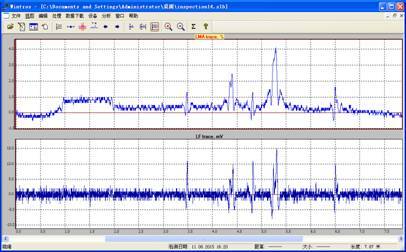

3. Software Data Processing

After downloading the data, the detection curve can be played back, analyzed, enlarged and reduced, compared, filtered, cut, spliced, printed, annotated, reported and exported to Word or Excel on the PC.

System requirements: Windows 7/ 10 / XP;

The following figure shows the results of a typical damage inspection

4. Product advantages

The technology of wire rope detection and residual life prediction is in an international position. It has provided non-destructive testing equipment and services to more than 100 companies or laboratories in 33 countries around the world. International companies such as Bouton in the United Kingdom and Beyond in the United States are using our products and technologies.

★The real realization of LMA and LF dual-channel synchronous detection has obvious advantages in the identification of major damage types such as internal and external broken wires, slippery wires, and corrosion.

★Replaced sensor and wear bushing.

★The residual strength can be evaluated.

★The protective coating of the bridge cable does not affect the inspection, and the inspection does not damage the protective coating.

★Real-time output, stop and check, the body can be separated, data storage and download convenient

5. Detection scheme

The bridge cable wire rope detector selects the appropriate detection magnetic head, fixing method and traction method. The traction recommend adopts the ground fixed simple winch as the power, and the special power traction robot can also be selected. Simple winch economy is good, simple, stable and reliable, strong adaptability, only in special places can not use the winch to consider the use of power traction robot, the current degree of reliability is slightly lower, adaptability, endurance and other overall performance is not ideal.

On-site bridge cable wire rope inspection/flaw detection picture

Personnel and Metrology Qualification

Previous:CNC rope groove turning device

Related recommend

Product inquiry

Sorry, the current column is being updated, please look forward to it!

You can view other columns or returnHome Page